Maxbo’s Cutting-Edge Photovoltaic Panel Factory>>

Efficient and Comprehensive Processing Equipment

Maxbo’s photovoltaic panel factory stands out with an array of advanced processing equipment, covering everything from silicon wafer production to automated packaging.

Ensuring Quality Throughout Production

This machinery collaborates seamlessly, ensuring an efficient, stable, and high-quality production process. From multi-step silicon wafer production to extensive experience in cell manufacturing, our facility is dedicated to maintaining superior standards.

Advanced Technology for Solar Cell Excellence

Advanced cell connection technology, rigorous testing, and meticulous encapsulation processes guarantee the top-tier performance and quality of each solar cell.

Precision Assembly and Robust Support

The automated component assembly line ensures precise assembly, combining cells, glass, frames, and other components. Specialized materials in cell backboard production provide robust support.

Comprehensive Quality Assessment and Secure Packaging

Photovoltaic panel testing equipment comprehensively assesses performance and quality, while automated packaging equipment ensures secure packaging for transportation.

Driving Clean Energy Innovations

Maxbo integrates the latest technology, continuously innovating to provide exceptional photovoltaic solutions and drive advancements in the clean energy industry.

<< Maxbo’s Photovoltaic Inverter Factory

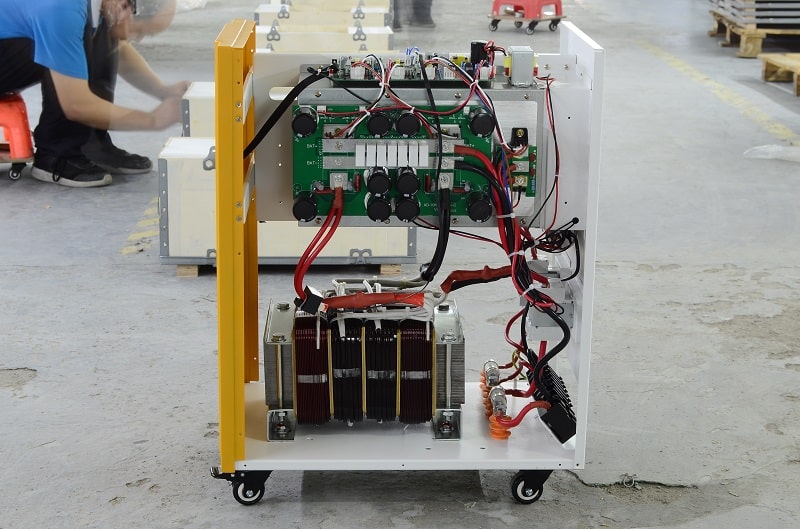

Cutting-Edge Equipment

Maxbo’s photovoltaic inverter factory is equipped with state-of-the-art Surface Mount Technology (SMT) equipment, wave soldering equipment, automated assembly lines, and various other cutting-edge machinery.

Automated and Efficient Production Process

These devices work cohesively to achieve an automated and efficient production process for Maxbo’s photovoltaic inverters. This process includes the precise assembly of circuit boards, installation of components, manufacturing of mechanical parts, coating, and comprehensive testing and quality inspection.

Ensuring Highest Quality Standards

The entire production process is designed to ensure that the photovoltaic inverters meet the highest standards of quality. From the initial assembly of circuit boards to the final testing and quality inspection, each step is meticulously executed.

Diverse Range of Photovoltaic Inverters

Maxbo’s extensive range of photovoltaic inverters includes independent inverters, grid-tie inverters, hybrid inverters, microinverters, string inverters, and central inverters. Each type caters to different application scenarios and requirements, providing versatile solutions for various solar energy setups.

Maxbo’s Advanced Lithium Battery Factory >>

Cutting-Edge Production Equipment

Maxbo’s lithium battery factory is equipped with cutting-edge production equipment, ensuring precision in every step of battery manufacturing.

Precision in Battery Cell Production

Specialized machinery, including coating equipment, winding machines, spot welding machines, vacuum sealing machines, and electrolyte filling equipment, ensures precision in battery cell production.

Structural Integrity and Stability

Formation presses play a vital role in shaping and compressing batteries, ensuring their structural integrity and internal stability.

Thorough Testing for Performance and Safety

Various testing equipment is integrated into the production process for a comprehensive examination of battery performance and safety.

Efficient Automated Production Line

The entire production process is seamlessly managed through an automated production line, enhancing efficiency and maintaining consistent product quality.

Commitment to Outstanding Performance

Harmoniously working together, these devices reflect Maxbo’s commitment to delivering lithium batteries of outstanding performance and high quality.

GET IN TOUCH